Mylar bags are indispensable for preserving dry foods, sensitive electronics and other items because they combine a gas‑ and moisture‑barrier film with a durable outer layer. In everyday language “Mylar” often refers to bags made from biaxially oriented polyethylene terephthalate (BoPET), a polyester film originally developed by DuPont and still widely used in packaging. People search for what Mylar bags are, how they are made, why they work so well and how to use them correctly. This article answers those questions and provides practical advice for choosing and using Mylar packaging.

What Is Mylar?

Mylar is a registered trade name for BoPET (biaxially oriented polyethylene terephthalate) film. The film is formed by stretching polyethylene terephthalate in two directions to create a strong, dimensionally stable, clear polyester. When this film is metallized with a thin layer of aluminium or laminated to aluminium foil, it becomes much less permeable to gases and moisture and reflects up to 99% of light. BoPET’s high tensile strength, chemical stability and electrical insulation make it useful for flexible packaging, electronics, insulation and more. Laminates containing metallized BoPET protect food against oxidation and aroma loss.

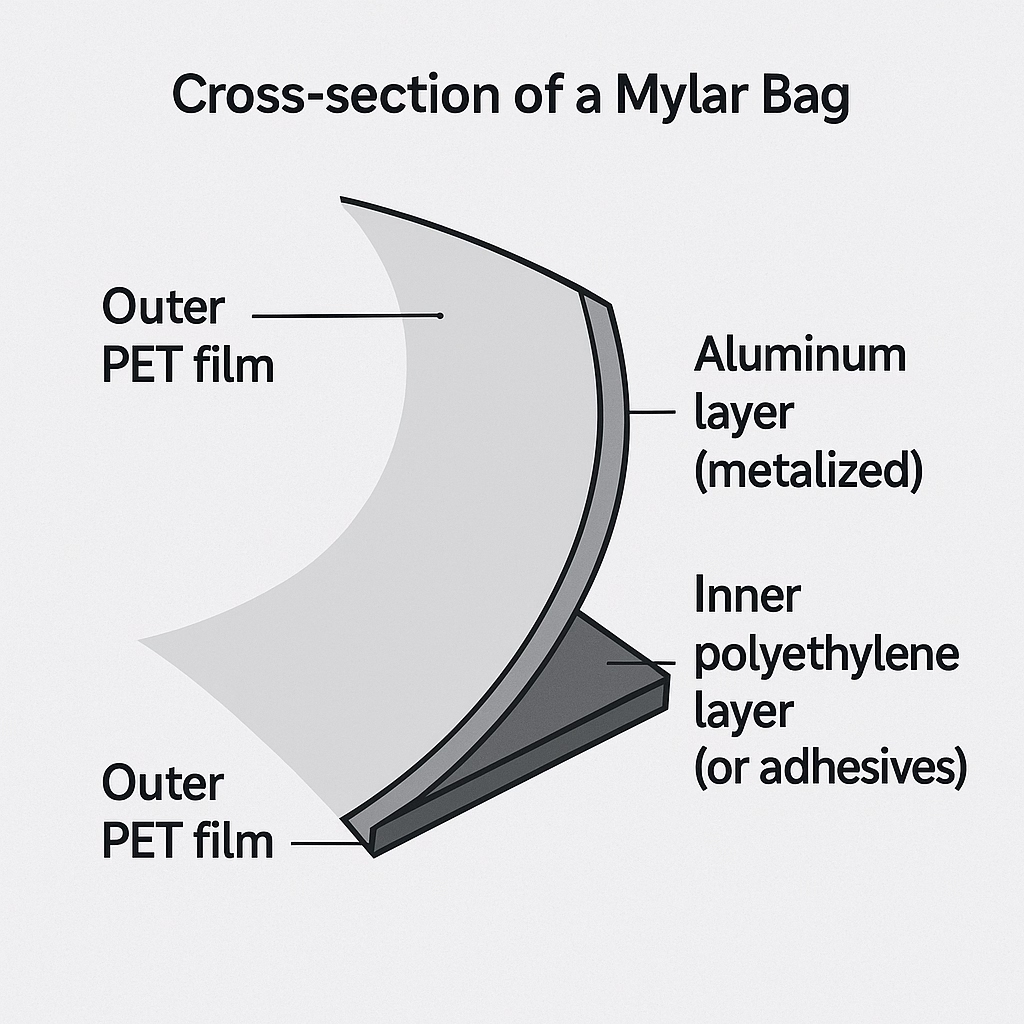

What Are Mylar Bags Made Of?

Mylar bags are composed of multiple layers. The core of the structure is the clear polyester (PET) film discussed above. In premium bags a vapor‑deposited layer of aluminium or a thicker aluminium foil is bonded to the PET, and an inner layer of polyethylene provides heat‑sealability.

- Clear polyester (PET) outer film – provides tensile strength and dimensional stability.

- Aluminium barrier layer – vapor‑deposited or laminated aluminium creates the oxygen and moisture barrier.

- Polyethylene inner layer – enables heat sealing and improves puncture resistance.

Why Use Mylar Bags? Benefits and Advantages

Mylar bags are valued because they protect contents from oxygen, moisture, light and odors. The gas‑ and moisture‑barrier properties of metallized BoPET are why Mylar bags are used to package food, beverages, pharmaceuticals, medical devices, cosmetics and other products.

- Long shelf life – Properly sealed Mylar bags block oxygen and water vapor to prevent spoilage and extend shelf life. Inkable Label notes that Mylar’s PET film provides excellent gas and smell barrier properties and high tensile strength.

- Strength and durability – The polyester substrate gives Mylar bags high tensile strength and chemical stability, while lamination to aluminium foil increases puncture resistance. Small bags can protect sensitive electronics or precious metals from moisture and damage.

- Lightweight & flexible – Mylar is thin and lightweight yet strong. Custom packaging companies emphasise that these bags are easy to transport but still hold significant weight.

- Odor & light protection – Aluminium layers block light that can degrade nutrients and flavours, and the sealed structure prevents odors from escaping.

- Heat sealable & resealable – The inner polyethylene layer allows bags to be sealed with a heat sealer, clothes iron or hair straightener, ensuring an airtight closure. Some models include zippers for resealing.

Common Daily Uses of Mylar Bags

Because Mylar bags create an effective barrier against oxygen, moisture and light, they are used in many industries and applications.

- Food storage – The most common use is long‑term storage of dry goods such as sugar, flour, pasta, beans and dehydrated vegetables. These foods must be dry (≤ 10% moisture). White rice stores well; brown rice does not because its oil content causes rancidity.

- Electronics & precious items – Small Mylar bags protect electronics, circuit boards and even gold or silver bars from moisture and corrosion.

- Seeds & gardening supplies – The barrier keeps seeds dry and prevents germination during storage.

- Medical & pharmaceutical products – Pharmaceuticals benefit from a controlled environment free from moisture and oxygen, and Mylar meets FDA requirements for direct food and pharmaceutical contact.

- Promotional & retail packaging – Custom printed Mylar pouches enhance brand recognition and preserve products such as snacks, cannabis, cosmetics and pet treats.

What Foods Can and Cannot Be Stored in Mylar Bags

Only foods with low moisture (≤ 10%) and low oil content should be stored in Mylar bags. Oxygen absorbers are crucial for long‑term storage to remove residual oxygen and prevent spoilage.

Image Source: BoxAgency

The table below summarises suitable foods and those that are not recommended.

| Category | Foods to store | Foods to avoid |

| Grains & Legumes | White rice, wheat berries, oats, barley, beans, lentils | Brown rice; granola (oil content) |

| Baking supplies | Flour, sugar, powdered milk, salt, pasta | Yeast or mixes containing oils |

| Snack foods | Dry nuts, dehydrated fruits & vegetables | Oily nuts; jerky with fat; moist dried fruits |

| Garden seeds | Dried seeds sealed with oxygen absorbers | Sprouted or moist seeds |

Powdered milk must be non‑fat and very dry; store only in smaller bags and rotate regularly.

How to Use Mylar Bags: Step‑by‑Step

- Choose the right bag size and thickness – Bags thicker than 5 mil are recommended for long‑term storage. Choose sizes appropriate for your food (pint, quart, 1 gallon or larger).

- Prepare the food – Ensure foods are completely dry. Remove contaminants and measure quantities.

- Add oxygen absorbers – Place the correct number of oxygen absorber packets at the bottom of the bag to remove oxygen. Work quickly to minimise exposure.

- Fill the bag – Pour the dry food into the bag, leaving about 2.5 cm (1 inch) of headspace so you can compress and seal.

- Seal the bag – Use a heat sealer, clothes iron or hair straightener set to high cotton to create a continuous heat seal across the top. A second seal provides extra protection.

- Label and store – Write the contents and date on the bag. Place sealed bags in a rodent‑proof container and store in a cool, dark, dry place.

Choosing the Right Mylar Bag: Thickness and Features

When choosing Mylar bags, consider the thickness (measured in mils), size and features such as gussets and zip closures. Thicker bags offer better puncture resistance and barrier properties but are more difficult to seal. Bags of 5 mil per side (10 mil combined) or thicker are recommended for long‑term food storage. The table below outlines common bag types and their typical features.

Safety and Environmental Considerations

Mylar bags are manufactured from food‑grade materials and are generally BPA‑free. Reputable suppliers as UC Packages meet FDA requirements for direct food and pharmaceutical contact. Because Mylar is a form of polyester, it is chemically resistant and does not corrode. After use, Mylar bags can often be cleaned and reused for non‑food items. However, they are not biodegradable and should be recycled where facilities exist.

Custom Mylar Bag Solutions for Businesses

Custom printing and sizing transform functional Mylar bags into branded packaging. Businesses can choose colours, patterns, shapes and resealable features to match product identity and appeal to target customers. Custom bags are ideal for high‑end products or promotional giveaways. Sorbent Systems notes that 75% of their orders involve custom sizes, colours or printed designs. Because Mylar is strong yet thin, custom pouches can include windows, spouts or gussets without sacrificing barrier protection. For cannabis, coffee, cosmetics or pet treats, bespoke Mylar bags differentiate products and protect flavour and potency.

Common Myths and FAQs about Mylar Bags

Is Mylar the same as polyester?

Mylar is a brand name for a family of polyester films. The generic term is BoPET, and the material used in bags is polyethylene terephthalate.

Is Mylar a metal?

No. Mylar is a plastic film. The metallic appearance comes from an ultra‑thin layer of aluminium applied through vapor deposition.

Do Mylar bags need refrigeration?

No. Mylar bags preserve foods at room temperature when sealed with oxygen absorbers.

Can Mylar bags be reused?

Yes, if the bag has not been punctured or contaminated, it can be cleaned, dried thoroughly and reused for non‑food storage.

Are Mylar bags Faraday cages?

Mylar bags are not designed to protect electronics from electromagnetic pulses. Special Faraday bags use conductive materials and construction.

Final Words

Mylar bags are more than just shiny pouches – they are engineered multilayer films that block oxygen and moisture, resist punctures and preserve freshness. Whether you are a home cook building emergency food reserves or a business looking for premium custom packaging, selecting the right Mylar bag will protect your investment.

For hobbyists, start with food‑grade bags thicker than 5 mil and always use oxygen absorbers. For businesses, explore our custom Mylar bag solutions, where you can specify size, thickness and print to create packaging that showcases your brand. Browse our custom Mylar packaging options to find stand‑up pouches, gusseted bags, spout pouches and more.